This post may contain affiliate links which help support Zestuous.

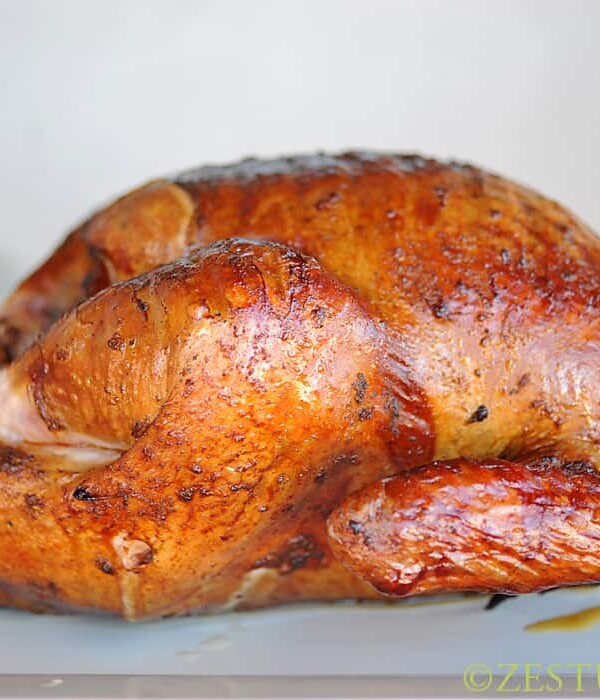

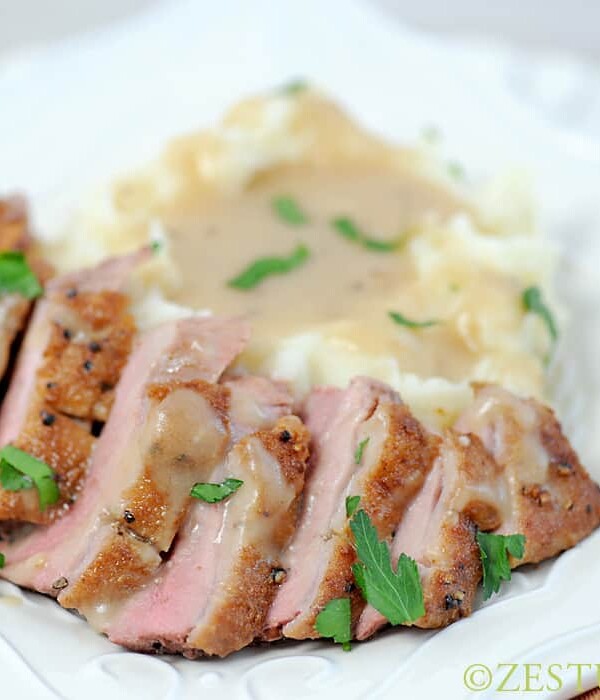

This is the first in a 3-part series about Maple Leaf Farms duck. I was invited to attend their first Blogger Duck University and am officially a new fan of this protein option. Follow the series to see how the ducks are farmed, how a Master Chef prepares the lean red meat and the secret to preparing it at home.

This is the first in a 3-part series about Maple Leaf Farms duck. I was invited to attend their first Blogger Duck University and am officially a new fan of this protein option. Follow the series to see how the ducks are farmed, how a Master Chef prepares the lean red meat and the secret to preparing it at home.

It’s long been said, “You are what you eat.” But what about what what you eat eats?

What an animal eats before becoming your latest meal is important. I didn’t have a true understanding of that until I visited Maple Leaf Farms World Headquarters as part of their first Blogger Duck University.

Our first stop was to their sole feed mill. The company produces 13-15 million ducks a year, and they are all fed a special formula pellet created at a 1978 mill in Indiana. Keith Rylands, the mill manager who has been with the company for 32 years, provided us with a tour.

Our first stop was to their sole feed mill. The company produces 13-15 million ducks a year, and they are all fed a special formula pellet created at a 1978 mill in Indiana. Keith Rylands, the mill manager who has been with the company for 32 years, provided us with a tour.

Locally grown soy was being dumped as we arrived. The soy, corn and wheat are all analyzed in a laboratory on-site for mineral content. Then, they’re mixed with other nutritional elements to create pellets for different stages in the duck’s development.

“We do a whole lot of testing and sampling to make sure that we’re doing it correctly,” said Keith.

“We do a whole lot of testing and sampling to make sure that we’re doing it correctly,” said Keith.

Each batch is analyzed a final time and samples are recorded for quality control.

A proven breeding stock of ducks produce eggs that are taken to a spacious grow house after they hatch. There, they are fed starter feed. We toured a farm where 12,600 ducks were 15 days old. I was impressed with how clean each bird was and how comfortable they seemed.

A proven breeding stock of ducks produce eggs that are taken to a spacious grow house after they hatch. There, they are fed starter feed. We toured a farm where 12,600 ducks were 15 days old. I was impressed with how clean each bird was and how comfortable they seemed.

Janelle Deatsman, the communications manager for Maple Leaf Farms, stressed how important cleanliness is to the company. She said biotech is the key to disease prevention and ultimately food safety. We were required to wear plastic booties, a suit and hairnet before going into the house, so we didn’t introduce disease to the healthy ducks.

Janelle Deatsman, the communications manager for Maple Leaf Farms, stressed how important cleanliness is to the company. She said biotech is the key to disease prevention and ultimately food safety. We were required to wear plastic booties, a suit and hairnet before going into the house, so we didn’t introduce disease to the healthy ducks.

Free range or caged?

One student asked why the birds weren’t raised in an open range. That seems to be all the hype now, claiming to be the more “humane approach.” Another student, who grew up on a farm, said no matter how much room you give the birds, they still like to flock together. She said raising birds in barns is very humane, so long as the density is appropriate.

Janelle agreed and added that if you raise the birds in a free-range environment, you have the risk of introducing disease, predators and other uncontrolled items that can jeopardize food safety and the ducks. The grow houses provide for their well-being with plenty of room, warmth, specially formulated food and clean water, which results in a safer product for consumers.

When we walked into the barn, I immediately noticed how spacious it was. Even with all the birds, you could still park at least 3 cars inside. Just as described, the birds were nestling together in groups. They waddled out of their groups when they wanted a sip of water or to nibble a few pellets, and then they returned to their roommates.

I can’t speak for all farm-raised birds, but at Maple Leaf Farms, they were being raised in what I thought was a more humane environment than the field just outside. They were clean, healthy, had plenty of food and water and seemed comfortable.

I can’t speak for all farm-raised birds, but at Maple Leaf Farms, they were being raised in what I thought was a more humane environment than the field just outside. They were clean, healthy, had plenty of food and water and seemed comfortable.

Processing

After the birds grow to about 30 days old, they waddle onto the trailer to the processing plant. I wasn’t sure how I was going to react at the plant. This is where the bird meets its fate. Meat eaters understand that the animals we eat were once living, but most people prefer to see their favorite cuts wrapped in plastic at the grocery. It’s a process many, including myself, take for granted.

The plant manager expressed the utmost respect for each bird. He said their well-being is important even in the final minutes. I was so pleased to learn that the “deed” was conducted in less than 3 seconds. I won’t go into the process, but it sounds painless and quick.

The plant manager expressed the utmost respect for each bird. He said their well-being is important even in the final minutes. I was so pleased to learn that the “deed” was conducted in less than 3 seconds. I won’t go into the process, but it sounds painless and quick.

From bill to tail

The respect Maple Leaf Farms shows for the birds continues through processing. Every part of the bird is appreciated. The feathers are used in luxury down linens, and the heads and feet are exported to China. USDA Grade A birds are bagged whole and other birds are parted out into breasts, ready-to-eat products and ground meat. Remaining parts are used in pet foods.

As the leading Pekin duck producer in North America, the plant processes 30,000 birds a day that are shipped to restaurants and groceries around the world. The products are available online, and the company is working to make it available at more retailers.

It was an eye-opening experience that strengthened by value and appreciation for the lives of the animals that we eat.

It was very interesting reading and I’m so glad you shared your experience with us. I do have to agree with Lisa Keys and sparing us the processing part. We once raised a Turkey and took it to a processing plant. I could not eat that Turkey. I felt like I would be eating a member of the family. I’m with most of the others and am rather OK buying it packaged. Thanks for sharing!

thank you for sparing us the details of the death process. Had I heard more I probably would never eat a bird again